The U.S. electrical grid is aging and not evolving quickly enough to accommodate the shift towards cleaner energy sources. Despite the pressing need to revamp and expand the grid, constructing new transmission lines remains a daunting task, likened to “herding cats.” Over 1,000 gigawatts of potential clean energy projects are stuck in limbo, primarily due…

Read more

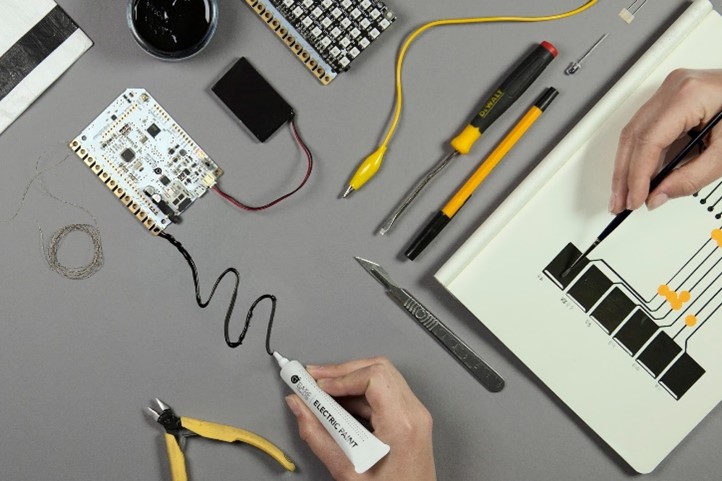

Electrically conductive paint is created by mixing a conductive pigment into a non-conductive resin binder. Adhesion comes from the binder that holds the paint together, and conduction is formed from the filler pigment. Electrical charges move through the conductive fillers and work best when they are highly concentrated, shaped like flakes or tubes. Spheres are…

Read more

Throughout the United States, construction spending by manufacturers more than doubled through 2022, according to the Census Bureau. Billions of dollars in subsidies handed out by the government have spiked the EV (electric vehicle), semiconductor, and solar panel industries. Not only did production numbers increase, but factories themselves swelled. Compared to $90 billion in June…

Read more

In September 2007, Jim Ozzello and Phil Delavy decided to take their combined 38 years of experience and form J&P Electrical Company. In 2012, Jason Ozzello officially became a co-owner of the company. Since Phil’s retirement, J&P has been a family-owned and operated business; owners Jason and Jim and brothers David and Jacob all work with…

Read more

Busway and bus duct power distribution systems are used in both commercial and industrial situations to transmit electrical power safely and efficiently from the source to the loads. Delivering flexible and reliable power dispersal, they differ in construction, installation, and application. In 2021, the global busway- duct market size was valued at $12.1 billion. By…

Read more

Isolated-Phase Bus (IPB) systems are vital in transferring bulk electricity through the grid. For decades, IPBs have been centered around the original designs from General Electric (GE) and Westinghouse, which led the industry. Now, improvements to insulators, mountings, and housings have elevated the model, making them even more reliable. IPBs transfer a power plant’s heavy…

Read more

The anaerobic adhesives market is set to reach $738.32 million by 2026 and was valued at $461.8 million in 2018, making the CAGR from 2019 to 2026 estimated at 6.01 percent. But what are these mysterious adhesives? Read on to find out. The definition of “anaerobic” is the absence of air. So anaerobic adhesives require…

Read more

The United States federal government is slated to deliver heavy funding for infrastructure projects in the upcoming years. The onshoring boom starting to take hold makes it a better time than ever to invest in specific stocks focused on infrastructure. The infrastructure law will boost the funding of many American infrastructure companies as a growing…

Read more

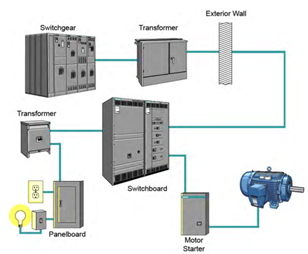

A building’s electrical system is a complex and critical infrastructure few know much about. Most people take advantage of flipping a switch and receiving automated light or functionality from a machine without much consideration of how it occurs. This blog introduces a few major products that make it all possible: panelboards, switchboards, and switchgear. …

Read more