The 2024 Electrical Contractor Industry Report, published by NECA and developed by Renaissance Research and Consulting, presents significant industry growth and evolving trends. The comprehensive analysis, spanning over 100 pages with a 14-page summary, captures a current snapshot of the industry including firm sizes, revenue, demographic shifts, and project types. Key insights include: Firm and…

Read more

Electrical transformers are crucial components for managing and distributing electrical energy across various sectors, including heavy-industrial settings. For companies specializing in providing new surplus and refurbished heavy-industrial electrical components, it’s essential to understand the critical role these transformers play. Here’s an overview for those sourcing and utilizing these powerhouses in their industrial operations. What is…

Read more

In the ever-evolving landscape of heavy industrial electrical supply, staying ahead of the curve means keeping a close eye on emerging trends and technological advancements. As industries pivot toward more efficient, sustainable, and innovative solutions, the heavy electrical supply sector is experiencing significant transformations. In this blog post, we review the key trends shaping the…

Read more

In today’s environmentally conscious world, industries are continuously seeking strategies to reduce their ecological footprint while maintaining efficiency and cutting costs. One effective strategy that is gaining traction is the use of refurbished industrial electrical equipment. This approach not only offers a cost-effective alternative to purchasing new equipment but also plays a significant role in…

Read more

General Electric (GE) is on the verge of a major transformation as it pivots towards focusing exclusively on aerospace and defense, shedding its previous identity as a diversified conglomerate. This transition is underscored by the impending launch of GE Aerospace as an independent company on April 2, which will retain the original GE stock ticker….

Read more

An electrical tap box is a crucial device used in both portable and permanent power distribution setups. Often referred to as splitter boxes or pull boxes, these units are specialized junction boxes that feature a backplate equipped with copper busbars for each electrical phase and mechanical lugs. These lugs are designed to connect with large…

Read more

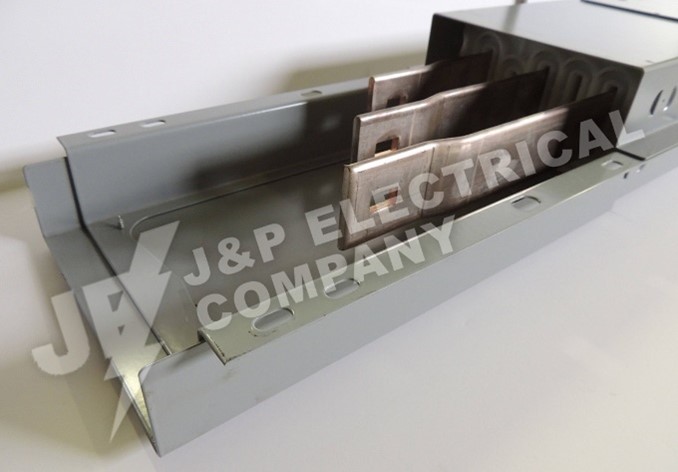

Busbars refer to metallic bars or strips which carry electrical current within electrical switchgear. These busbars are incorporated into bus ducts, a type of sheet metal duct that houses a sequence of busbars. Bus ducts offer an efficient and adaptable alternative to conventional conduits for electrical installations, simplifying the process of installation and modification. Bus…

Read more

Here at J&P, we are all too familiar with the heartache that comes from losing a loved one far too soon. Cancer is the second-leading cause of death worldwide. Ten million people die from cancer every year. A donation to the American Cancer Society is more than a financial gift. It is a lifeline for…

Read more

There are countless reasons for us to feel gratitude, and you, our esteemed customer, are certainly one of them! We at J&P Electrical immensely appreciate the incredible loyalty and support we receive from our valued clientele. Here are just a few who have reached out to let us know how we have helped: “I must…

Read more