Most standardized procedures aren’t developed overnight. Rather, they can take years to form with help from stakeholders, owners, employees, and more. With the invention of the Internet, advanced technology can simplify and complicate standards that might have already been in place. Developing codes is an intricate process with much to take into consideration. First, there…

Read more

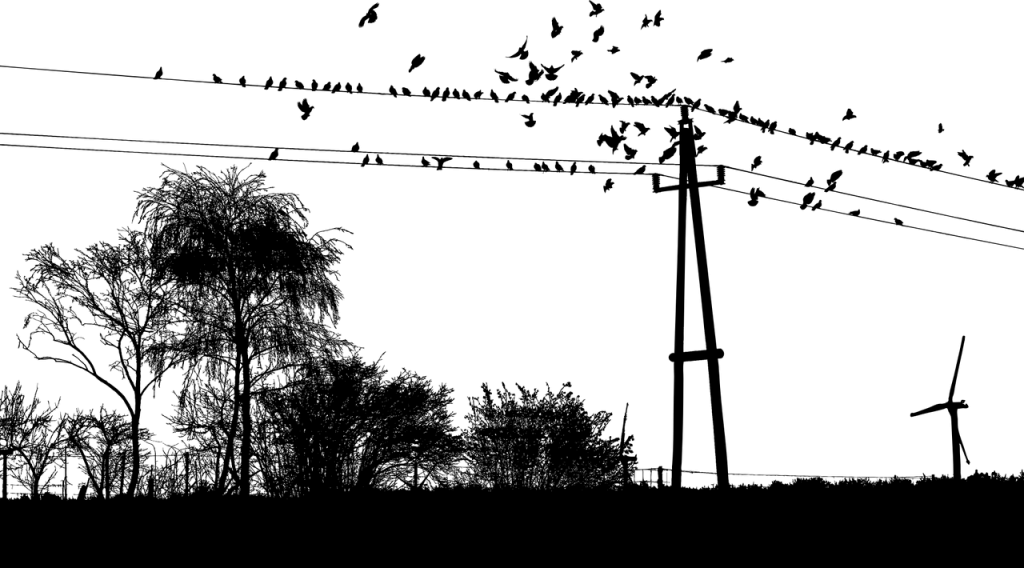

For safe and reliable electrical transmission, bushhogging, seeding, and herbicides are used to control weeds. Along high-voltage power line corridors and local distribution systems, a low profile must be implemented so trees and other tall vegetation do not fall onto lines. Tree branches and shrubbery meeting power lines equals interference sparking outages, wildfires, and other…

Read more March 29, 2021Now that construction activity is starting to ramp up again following the COVID-19 pandemic, a familiar issue is facing the industry: labor shortages. Total hires and job openings within the industry as of Dec. 31, 2020 were down slightly from 2019 before the pandemic forced shutdowns and industry layoffs. The 2020 Marcum JOLTS Analysis showed…

Read more